1

/

de

6

REA

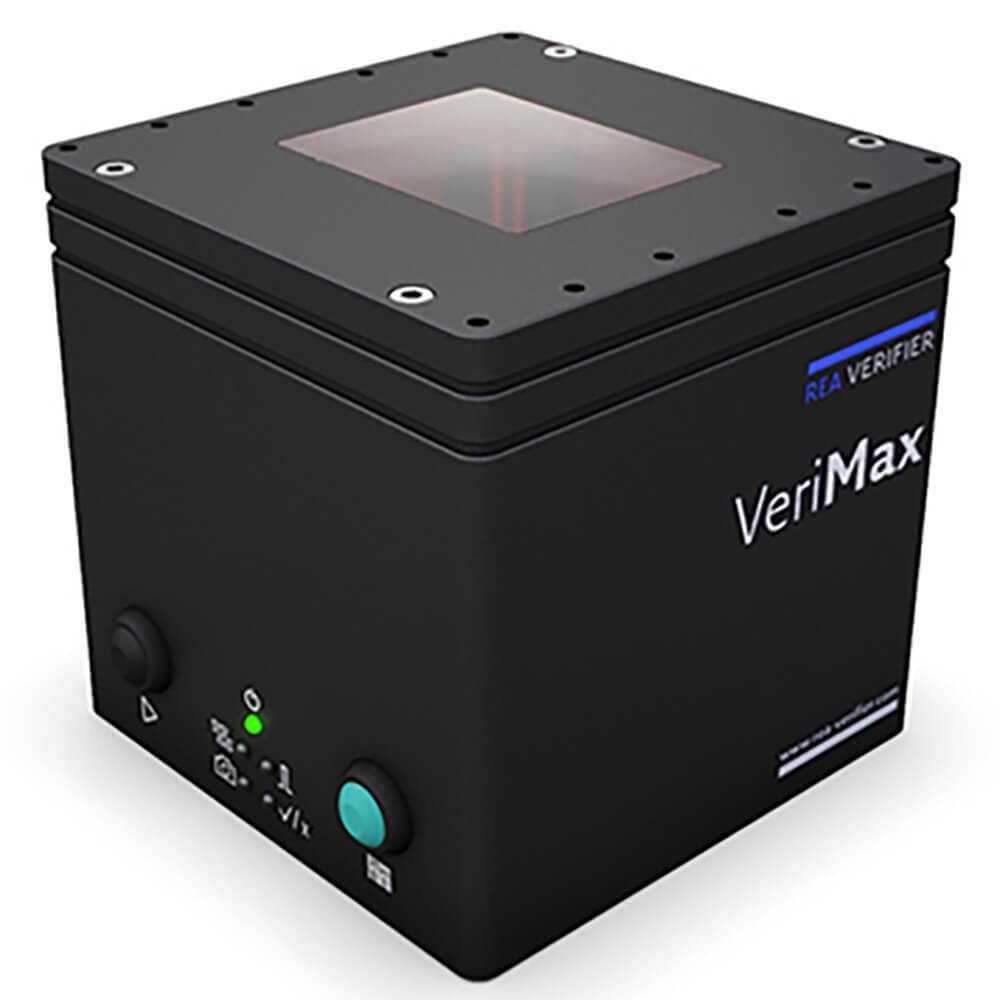

REA VeriMax

REA VeriMax

Preço normal

$5,880.00 USD

Preço normal

Preço de saldo

$5,880.00 USD

Preço unitário

/

por

Imposto incluído.

Envio calculado na finalização da compra.

Não foi possível carregar a disponibilidade de recolha

REA VeriMax

Matrix Code Verification Systems

The REA VeriMax is a verification system for 1D barcodes and 2D matrix codes, specially designed for fully integrated installation in production lines. Due to its two operating modes, the REA VeriMax can be used individually in the production line according to the requirements: Either for manual random verification or as an inline verification system.

The more complex the codes, the more complex the task for an inline code verification system. The REA VeriMax can reliably verify up to five complex codes per second inline. If the codes are simplified in their complexity, the verification rate of the REA VeriMax per second also increases.

Due to its small dimensions and with software individually programmed by the machine manufacturer, the REA VeriMax finds its place in every plant. The appropriate interfaces and the software for the evaluation of your codes come from REA.

The measurement of optical codes in compliance with defined angles, distances and illuminations enables accurate and reproducible measurement results and quality evaluations according to ISO / IEC standards.

In addition to fully integrated installation in production lines, the REA VeriMax can also be mounted on a stand as a standalone code verification system.

Product Details

-

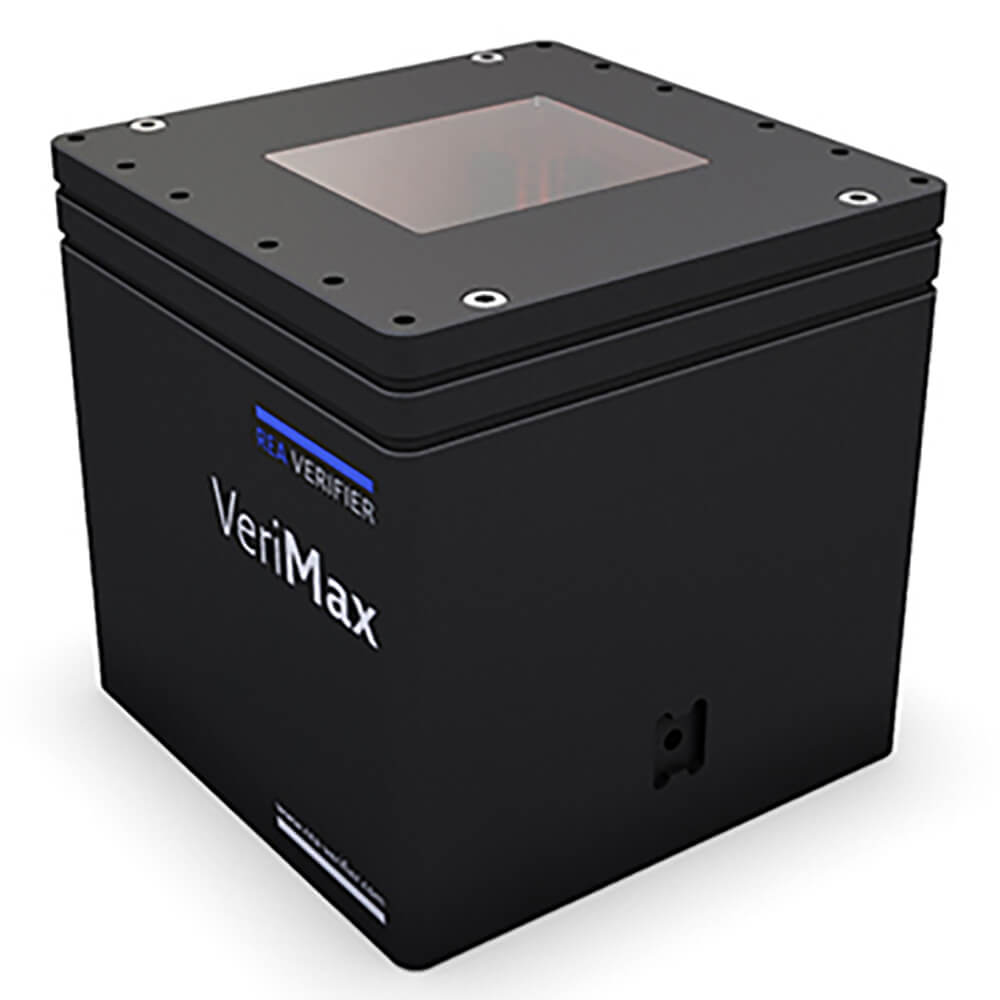

Modern, inline and offline 2D matrix code and 1D barcode verification system

-

Full integration into machines and plants, ideal for mechanical engineers and OEMs or as standalone verification device with stand solution

-

Two operating modes: automatic inline code verification on the fly or manual measurement of random samples

-

Removable top cover plate with replaceable glass plate and thread for fixture mounting

-

Fixed mounted lens for highest precision

-

Darkened measuring chamber to avoid ambient light influences

-

Housing milled from solid aluminum, protection class IP54

Features

-

Contact-free code verification by CMOS camera

-

Red light illumination 660 nm, 45° from four sides

-

Verification according to ISO/IEC 15415 for printed 2D matrix codes and ISO/IEC 15416 for printed 1D barcodes

-

Verification according to ISO/IEC TR 29158 (former AIM DPM-2006 guideline) for direct marking of 2D matrix codes (optional)

-

Verification according to GS1 specification according to GS1 Data structure

-

Verification of optional parameters for optimizing the print process

-

Multilingual user interface and reports

-

Settings for user-defined profiles, for easy operation and faster selection

-

ISO/IEC 15418 / ANS MH10.8.2 Data structure analysis

-

Specific code selection to meet the requirements of the pharmaceutical industry

-

24 Volt power supply for machine integration. A separate 24 V power supply is available for standalone operation / evaluation kit

Technical Data

-

Code verification system and measuring accuracy compliant to ISO/IEC 15426-2 and ISO/IEC 15426-1

-

REA VeriMax Software for Windows included

-

Red light-LED 660nm

-

Illumination angle 45°, red from four sides

-

Separate Power supply for REA VeriMax 24V (excluded in OEM version, included in evaluation kit)

-

M12 Ethernet connection for GigE Vision communication (connection cable optionally available)

-

Camera resolution 1280 x 1024 pixel

-

Camera focus and aperture pre-adjusted by factory

-

Depth in field 0 up + 2 mm

-

Size: 120 x 120 x 120 mm (w/l/h) with key panel 126 mm

-

Weight: 1560 g without connecting cable and brackets

-

Windows 7 and later, 64 bit support

-

ISO/IEC 15423 : Please note that this performance standard is valid for barcode and matrix codes scanners only. It does not apply to optical measuring instruments like the REA Verifier product range. For Verifiers ISO/IEC 15426-x are the appicable performance standards.

-

ISO/IEC 15419: Please note that this performance standard is valid for barcode and matrix codes labeling and code generation software as well as for printers printing QR-Codes, Data Matrix Codes and Barcodes.

Symbologies

2D Matrix Codes:

-

ISO/IEC 16022 Data Matrix

-

ISO/IEC 18004 QR-Code

-

ISO/IEC 24778 Aztec Code

-

ISO/IEC 20830 Han Xin Code

-

AIM ISS DotCode

-

ISO/IEC 15438 PDF417

-

ISO/IEC 24728 MicroPDF417

1D Barcodes:

-

ISO/IEC 24723 Composite Code

-

ISO/IEC 15420 EAN/UPC (EAN-13, EAN-A, UPC-A, UPC-E und Add-On)

-

ISO/IEC 15417 Code 128

-

ISO/IEC 16388 Code 39 (mit PZN und Code 32)

-

ISO/IEC 16390 Interleaved 2 of 5 einschließlich ITF-14

-

ISO/IEC 24724 GS1 DataBar

Optional Codes:

-

2/5 3 Bars, 2/5 5 Bars, 2/5 IATA, 2/5 Baggage, 2/5 DHL Express (Frachtpost-Code), Code39 Full ASCII, Code93, MSI, Plessey, Codabar Monarch (18), LAETUS Pharmacode, LAETUS Mini Pharma Code, Russian Crypto Code, China Drug Supervision Code, Japan CVS payment Code, UPU-S10 Postal Codes, DPD Parcel Service

Data structures and code properties:

-

GS1 data structures: GS1 DataMatrix, GS1 QR-Code, GS1-128, GS1 Databar, GS1 Composite Code), Crypto Code (GS1 General Specifications)

-

ISO data structures: ISO/IEC 15418 / ANSI MH10.8.2, ISO/IEC 15459 (part 1 to 8), ISO/IEC 15434 used by Issuing agencies and associations: AIAG, Odette, VDA, EDIFICE, HIBC, DOD, UPU, JEISA, JEITA, IFA …)

-

ISO 28219, ISO 22742, ISO 15394

-

EFPIA and PPN support for pharmaceutical industry (delegated Act EU 2016/161 and UDI/MDR 2017/745, 2017/746, US DSCSA, Turkey and more, US GUDID alignment (UDI)

-

DOD MilStd 130 IUID support, AIT (German Armed Forces)

-

Check digit control settings

-

Size control settings

-

Customizable date verification

-

Optional database (item number verification)

-

IKEA Data Matrix Code and IKEA interleaved 2 of 5 Code

Evaluation:

-

ISO/IEC 15416 for barcodes, ISO/IEC 15415 for 2D Codes

-

ISO/IEC 29158 and SAE AS 9132 for DPM

-

GB/T 14258 (China barcode), ANSI X3.182

Share

Subscribe to our emails

Be the first to know about new collections and exclusive offers.